high quality slurry pump for vapour blasting

Latest articles

If you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreWith the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreIf the exact in-pump viscosity of the product is unknown, CSI can help

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreThe winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read More>Slurry Pump

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreIt is often used if a short period of dry running is expected. Fluid is introduced into the area between the back of the seal face and the tight-fitting outlet on the drive side of the slurry pump.

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreThere are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreThe type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreNon-settling slurries consist of very fine particles that do not settle to the bottom of the pipe and do not settle for very long (i.e. weeks).

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read More

Popular articles

- Dry Installation

- I hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

- Pumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

- Slurry pump construction materials

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

- Typically, slurries are.

Latest articles

-

Pumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

-

The frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

-

how-does-a-dredge-pump-work

-

Aier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

-

Dredge pumps are designed to transfer large quantities of fluids and solids.

-

What is the optimum seal arrangement for the application?

Links

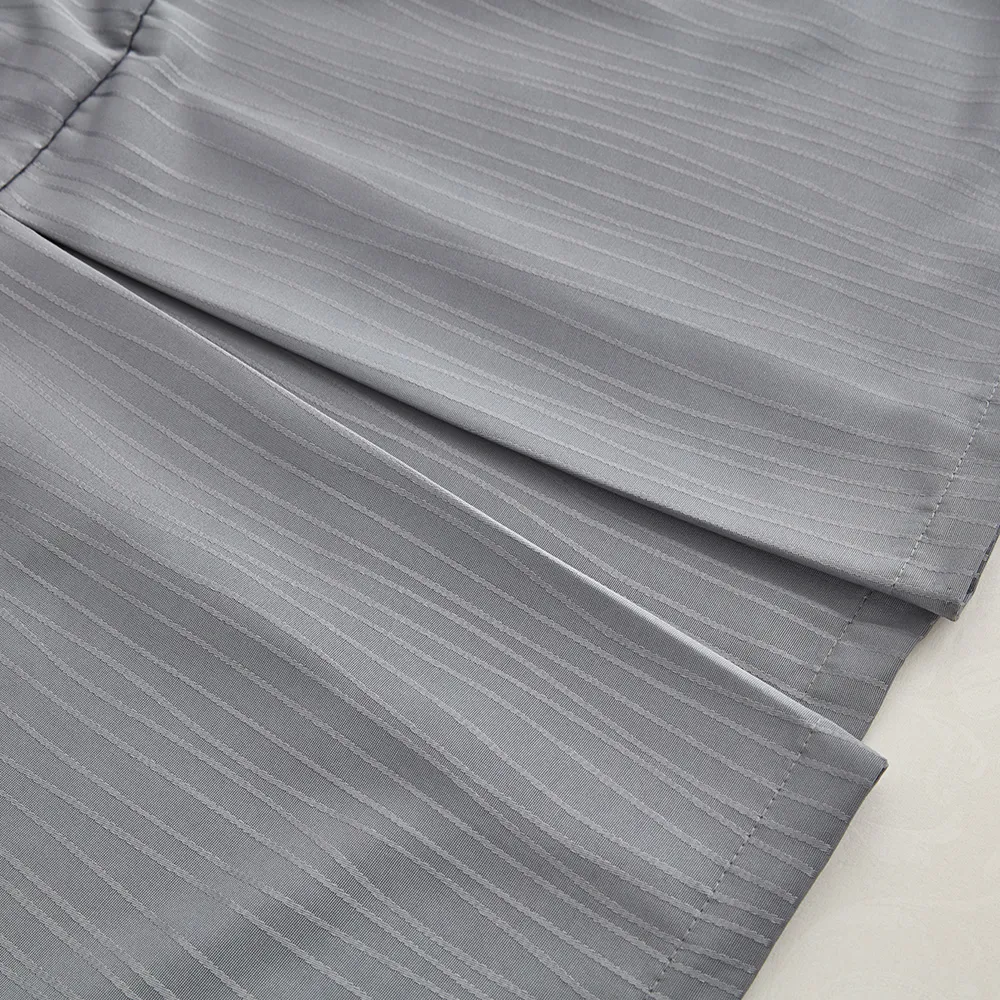

- In conclusion, extra long hospital bed sheets are a valuable addition to any healthcare facility. They offer better coverage, easier maintenance, and a more comfortable sleep environment for patients. As healthcare providers strive to create a warm and nurturing atmosphere for their patients, choosing the right bed linens is an important step in achieving this goal.

- A satin top sheet, often made from polyester or a blend of silk and synthetic fibers, boasts an incredibly soft texture that glides against the skin. The smoothness of satin reduces friction, making it an ideal choice for those with sensitive skin or prone to hair breakage. It's a game-changer for individuals who wake up with tangles or crease marks on their face due to rougher bedding materials.

Twill